服务热线

4001-123-456

4001-123-456

4001-123-456

4001-123-456

CATEGORY

Product Usage:

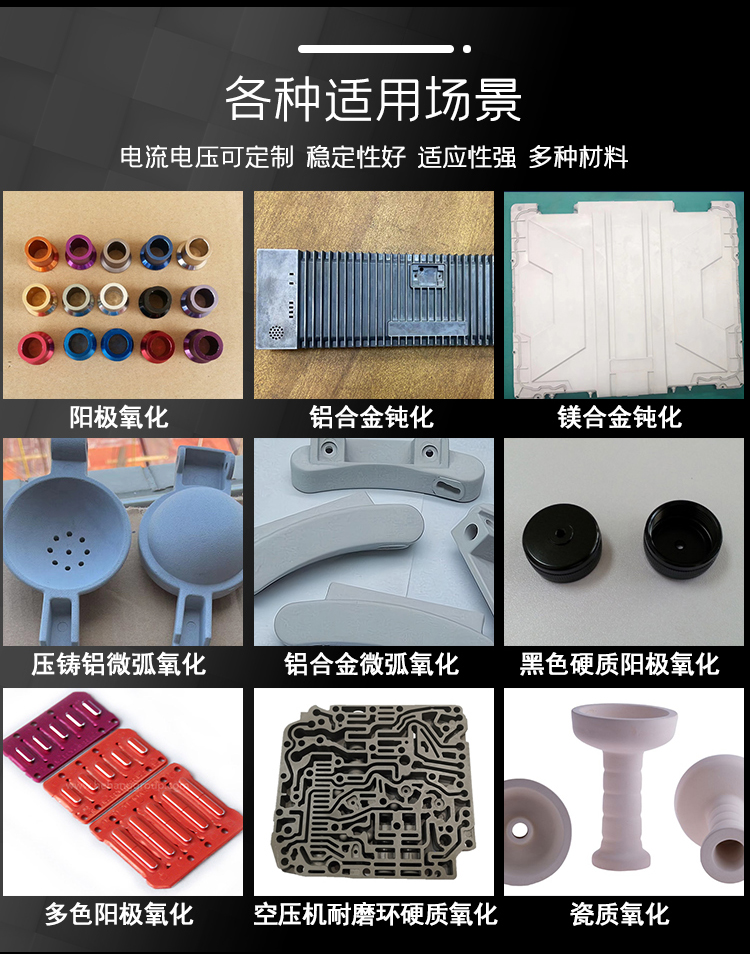

Mainly used in oxidation surface treatment fields such as aluminum oxidation,aluminum alloy oxidation,anodizing,hard oxidation,qualified oxidation,micro-ace oxidation,electrochemical polishing,oxidation coloring,etc.

Features:

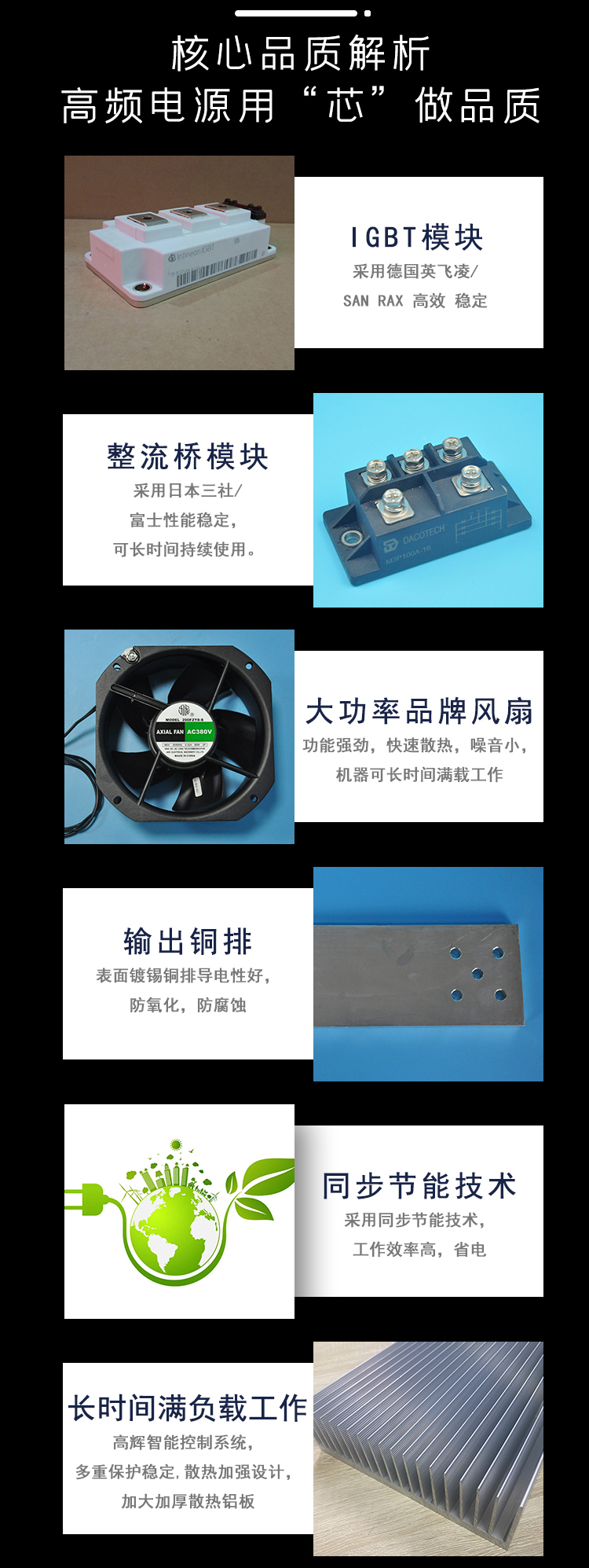

1.The performance of this series of power supply is much higher than the internationally advanced Italian CIS-ART or TECNO.

2.The front and rear edges of the pulse are both 90' vertical,which is ideal for electrochemical processes.

3.The height of pulse superposition level can be adjustable at will.

4.It has various protection functions such as phase loss,load short circuit,overcurrent and voltage.

5.When working in a stable voltage state,it has voltage limiting functions.

6.Pulse soft start is adjustable from 1 to 32 minutes,especially suitable for hard oxidation of aluminum.

7.The control accuracy can be within 1%,ensuring the high standards of uniformity,density and wear resistance of the oxide film.

8.Parameters can be modified at will during operation and stored at any time.The storage time is 20 years after power failure.

|

Arbitrary Output Current |

0-30000A(can be customized) |

|

Arbitrary Output Voltage |

0-1000V(can be customized) |

|

Stabilized Voltage Accuracy |

≤1% |

|

Stabilized Current Accuracy |

≤1% |

|

Stable Mode |

Steady current and limited pressure\Steady voltage and limited current can switch |

|

Adjustable Range |

Current/Voltage in 0-100% |

|

Input Voltage |

three phase AC 380±15% 50HZ |

|

Overall Efficiency |

≥90% |

|

Power Factor |

≥0.95 |

|

Ripple Coefficient |

≤3% Can be adjusted to lower accuracy requirements |

|

Working Limit |

Continuous full load operation |

|

Protect Way |

Input over voltage ,under voltage,over current ,output short circuit protection |

|

Over-heating Protection |

Posses the function of drive fault self-locking protections |

(There are so many different Types,Non-regularly can't be list completely.If you need Electronic brochures and customize models what U want).PLS contact sales:

KIMMY +86 13760727815(WTS)

Hard Anodizing Regular Type

electronic brochures and customize models what U want).PLS contact sales:

KIMMY +86 13760727815(WTS)

Oxidation Regular Type

Item NO.

Output Current(A)

Output Voltage(V)

Power(KW)

Input Current(A)

Inpue Voltage(V)

Weight(KG)

Width(W)*Length(L)*High(H)

YH200018

2000

18

36

60

380

50

400*500*630

YH300018

3000

18

54

90

380

70

400*500*630

YH300020

3000

20

60

100

380

100

500*670*1450

YH300024

3000

24

72

120

380

120

500*670*1450

YH400018

4000

18

72

120

380

120

500*670*1450

YH400020

4000

20

80

133

380

120

500*670*1450

YH400024

4000

24

96

160

380

120

500*670*1450

YH500018

5000

18

90

150

380

120

500*670*1450

YH500020

5000

20

100

167

380

120

500*670*1450

YH500024

5000

24

120

200

380

130

500*670*1450

YH600018

6000

18

108

180

380

130

500*670*1450

YH600020

6000

20

120

200

380

130

500*670*1450

YH600024

6000

24

144

240

380

180

500*670*1450

YH800018

8000

18

144

240

380

180

500*670*1450

YY200040

2000

40

80

133

380

130

450*620*920

YY200060

2000

60

120

200

380

150

600*750*1300

YY200080

2000

80

160

267

380

180

600*750*1300

YY300040

3000

40

120

200

380

200

600*750*1300

YY400050

4000

50

200

333

380

250

600*750*1300

YY400060

4000

60

240

400

380

250

600*750*1300

YY500050

5000

50

250

417

380

300

600*750*1300

YY500060

5000

60

300

500

380

300

600*750*1300

YY600060

6000

60

360

600

380

300

600*750*1300

YY600080

6000

80

480

800

380

300

600*750*1300

YY50150

50

150

7.5

13

380

40

420*500*320