服务热线

4001-123-456

4001-123-456

4001-123-456

4001-123-456

CATEGORY

Water treatment power supply rectifier uses:

Suitable for water treatment electrolysis, water extraction of metals, sewage treatment, seawater desalination, sodium hypochlorite electrolysis, Electrolytic descaling and other fields.

Water treatment power rectifier structure:

The water treatment power supply mainly consists of a rectifier and filter circuit, a full-bridge conversion circuit, a high-frequency transformer, a high-frequency rectifier and filter circuit, an auxiliary power circuit and a main control unit. The main control unit circuit mainly consists of a phase loss protection circuit, a temperature protection circuit, and an overload protection. circuit, short circuit protection circuit and PWM circuit with PI adjustment.

After the three-phase grid voltage passes through the power switch, it is rectified and filtered, and the resulting smooth DC voltage of 520V DC is supplied to the inverter circuit. The inverter circuit mainly consists of high-power field effect MOSFET modules or IGBT modules to form a full-bridge conversion circuit. When the PWM output control signal drives the power module respectively through the isolation driver, the two sets of diagonal tubes are alternately conducted, generating a high-frequency pulse voltage in the primary of the high-frequency transformer. The secondary voltage is transformed by the high-frequency transformer and rectified to provide energy to the load.

Features of water treatment power supply:

1. The power supply can work in a stable voltage and current limiting state or a stable current and voltage limiting state, and the two states can be switched at will.

2. The DC output voltage stabilization accuracy is 50%-100%. When the input voltage fluctuates by 10% or the load changes, the output voltage remains unchanged and the voltage stabilization accuracy is ≤0.5%.

3. It has a filtering function to prevent the power supply from interfering with the instrument, prevents the pollution of the power grid, and avoids the "good surge" phenomenon of current.

4. Phase loss protection: When the three-phase AC incoming line of the power supply loses a phase, the power supply will automatically block. After the fault is eliminated, the power supply will automatically resume work.

5. Overcurrent protection: When the current exceeds the rated value, the power supply automatically enters the overcurrent shutdown alarm state.

6. Short circuit protection: When the power load is short-circuited or the internal components of the power supply are short-circuited, the air switch automatically cuts off the power supply.

7. Over-temperature protection: When the power supply is used abnormally and the base temperature of IGBT, Schottky and other semiconductor devices is ≥80°C, the electronic switch in the main control board works and the power supply is in a blocked state, which can effectively protect the power supply.

product parameters

Input Voltage

three phase AC380V±10% 50~60Hz

Voltage stabilization Accuracy

≤1%

Current stabilization Accuracy

≤1%

Output DC Current

DC 0~±2000Aadjustable

Output DC Voltage

DC 0~±24V adjustable

Overall Efficiency:

≥90%

Cooling Method

Air-Cooling/Optional forward and reverse communication

Product Volume

510*580*920mm

Product Weight

130KG

Product Features

1、Small size and light weight:

the volume and weight are1/5-1/10 of the silicon controlled,making it easy for you to plan,expand and move ,maintain and install.

2、Good energy saving effect:

Since the switching power supply uses a high-frequency transformer,the conversion efficiency is greatly improved.Under the normal circumstances,the efficiency is more than 10% higher than of silicion-controlled equipment,When the load rate reaches below 70%,the efficiency is more than 30%higher than the equipment.

3、High output stability:

4.The output waveform is easy to modulate:

charged according to the user's process requirements.This has a stronge effect on improving work efficiency at the work site and improving the quality of processed products.

Due to the fast response speed of the system(microsecond level),it has stronge adaptability to network powerand load changes,and the output accuracy can be better than 1%.The switching Power Supply has high working efficiency,so the control accuracy is high,which is conductive to improving product quality.

Due to the high operating frequency,the output waveform adjustment has relatively low processing costs,and the output waveform can be easily

5.The latest technology in the industry,high precision,low ripple,can be overload for a long time,power margin >20%,20%energy saving than ordinary Power Supply.

|

Water Treatment Power Supply Regular Type Choice Form (if there haven't what you want,we support customize for free) |

|||||||

|

Type |

Outpur Current(A) |

Out put Voltage(V) |

Power(KW) |

Input Current(A) |

Input Voltage(V) |

Weight(KG) |

Width(W)*Length(L)*High(H) |

|

GH10024 |

100A |

24V |

2.4 |

12 |

220 |

17 |

380*400*170 |

|

GH100100 |

100A |

100V |

10 |

17 |

380 |

40 |

450*500*225 |

|

GH120100 |

120A |

100V |

12 |

20 |

380 |

40 |

450*500*225 |

|

GH20015 |

200A |

15V |

3 |

15 |

220 |

17 |

380*400*170 |

|

GH20024 |

200A |

24V |

4.8 |

8 |

380 |

40 |

450*500*225 |

|

GH20036 |

200A |

36V |

7.2 |

12 |

380 |

40 |

450*500*225 |

|

GH20048 |

200A |

48V |

9.6 |

16 |

380 |

40 |

450*500*225 |

|

GH200100 |

200A |

100V |

20 |

33 |

380 |

130 |

510*580*920 |

|

GH30024 |

300A |

24V |

7.2 |

12 |

380 |

40 |

450*500*225 |

|

GH30036 |

300A |

36V |

10.8 |

18 |

380 |

40 |

450*500*225 |

|

GH30048 |

300A |

48V |

14.4 |

24 |

380 |

95 |

510*580*690 |

|

GH300100 |

300A |

100V |

30 |

50 |

380 |

130 |

510*580*920 |

|

GH33030 |

330A |

30V |

9.9 |

16.5 |

380 |

40 |

450*500*225 |

|

GH40030 |

400A |

30V |

12 |

20 |

380 |

40 |

450*500*225 |

|

GH50024 |

500A |

24V |

12 |

20 |

380 |

95 |

510*580*690 |

|

GH50036 |

500A |

36V |

18 |

30 |

380 |

95 |

510*580*690 |

|

GH50048 |

500A |

48V |

24 |

40 |

380 |

95 |

510*580*690 |

|

GH50012 |

500A |

12V |

6 |

10 |

380 |

45 |

380*400*170 |

|

GH60048 |

600A |

48V |

28.8 |

48 |

380 |

95 |

510*580*920 |

|

GH100024 |

1000A |

24V |

24 |

40 |

380 |

95 |

510*580*690 |

|

GH100036 |

1000A |

36V |

36 |

60 |

380 |

130 |

510*580*920 |

|

GH100048 |

1000A |

48V |

48 |

80 |

380 |

130 |

510*580*920 |

|

GH100012 |

1000A |

12V |

12 |

20 |

380 |

45 |

480*525*310 |

|

GH200024 |

2000A |

24V |

48 |

80 |

380 |

130 |

510*580*920 |

|

GH300024 |

3000A |

24V |

72 |

120 |

380 |

165 |

530*600*1200 |

|

GH4000100 |

4000A |

100V |

400 |

667 |

380 |

195 |

580*650*1400 |

|

GH800036 |

8000A |

36V |

288 |

480 |

380 |

235 |

600*680*1600 |

|

GH1000036 |

10000A |

36V |

360 |

600 |

380 |

260 |

800*1350*1510 |

|

There are so many different Types,Non-regularly can't be list completely.If you need Electronic brochures and customize models what U want.PLS contact sales: KIMMY +86 13760727815(WTS) |

|||||||

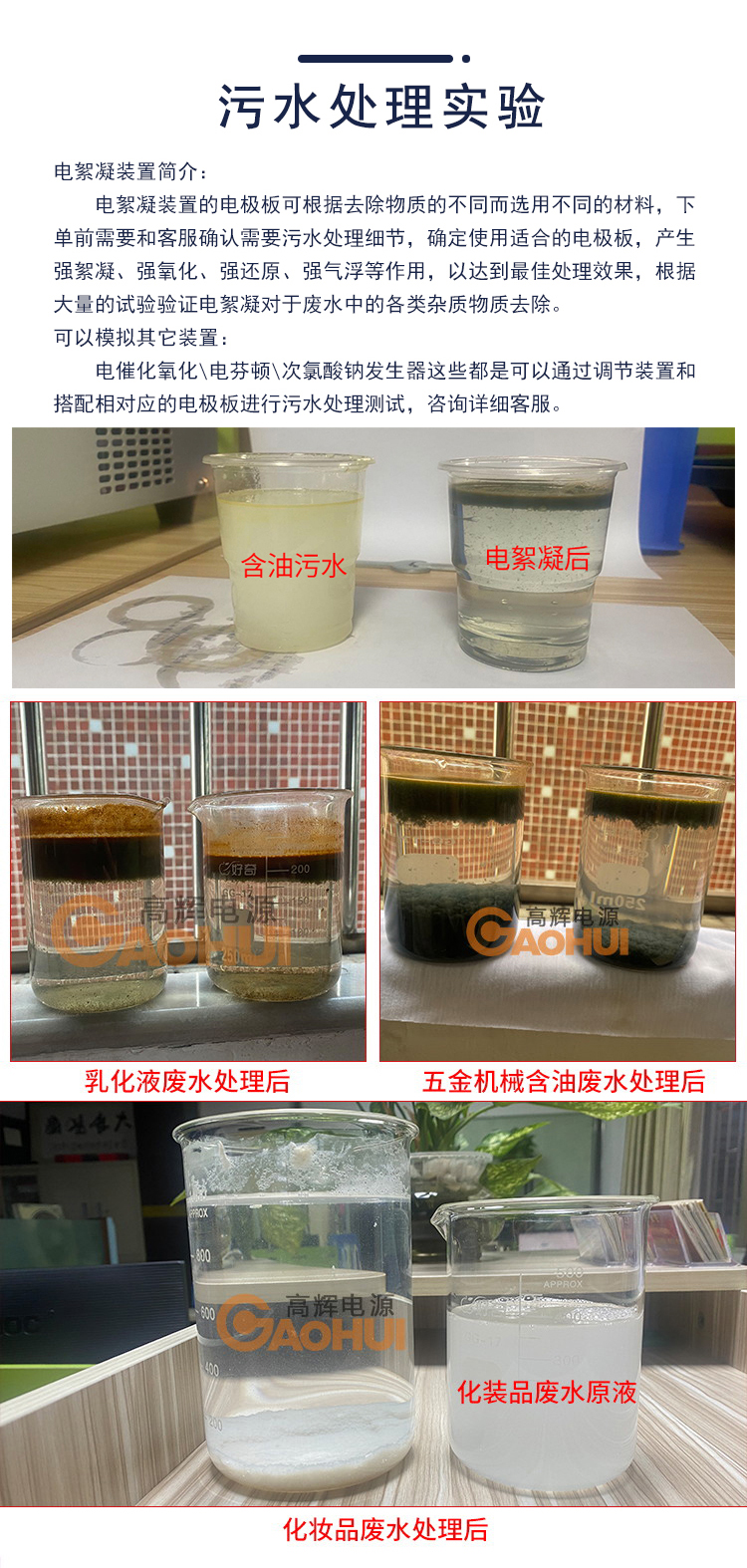

Real shot of electrocoagulation experiment

Focus on electrochemical water treatment power supply

Introduction of electrocoagulation device:

The electrode plates of the electrocoagulation device can be made of different materials according to the different substances to be removed.before placing an order,you need to confirm the details of the pollution treatment required with customer service to determine the use of suitable electrode plates to produce strong flocculation,stronge oxidation,strong reduction,and strong air flotation.and other functions to achieve the best treatment effect.according to a large number of experiments,it has been verified that electrocoagulation can remove various impurities in waste water.

Other devices can be emulated:

For sewage treatment experiments such as electrocoagulation,electric-fenton,and electrocatalytic oxidation(need to consult customer service),after testing the best rusults,the parameters can be recorded,which can be enlarged for project planning and cost budgeting.