服务热线

4001-123-456

4001-123-456

4001-123-456

4001-123-456

CATEGORY

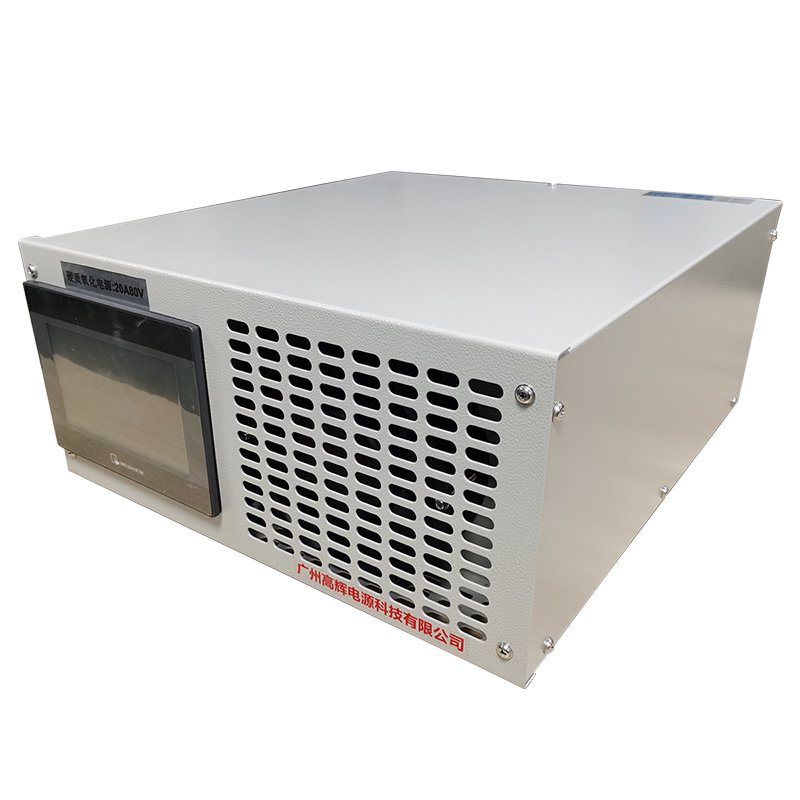

Single pulse micro-arc oxidation power supply

The micro-arc oxidation process, also known as plasma electrolytic oxidation, micro-plasma oxidation, etc., refers to a method of using arc discharge to enhance and activate the reaction at the anode on the basis of ordinary anodic oxidation, thereby forming a high-quality reinforced ceramic film on the surface of workpieces made of metals such as aluminum, titanium, magnesium and their alloys. It is a method of applying voltage to the workpiece with a dedicated micro-arc oxidation power supply, so that the metal on the surface of the workpiece interacts with the electrolyte solution, forming micro-arc discharge on the surface of the workpiece, and under the influence of high temperature, electric field and other factors, a ceramic film is formed on the metal surface, thereby achieving the purpose of strengthening the workpiece surface.

Product Parameters

1. Current stabilization or voltage stabilization function can be switched

2. Input voltage: AC380V±10% 50Hz

3. Output frequency: 100-3000Hz (customizable)

4. Occupancy Ratio: 5-100%

5. Pulse width time: 0.1-9999.9ms (adjustable)

6. Number of pulses: 0-9999 (adjustable)

7. IGBT chopping technology, DSP intelligent control technology

8. Single-stage and multi-stage operation can be set, and 50 processes can be saved

9. Positive pulse: 0-70% continuously adjustable, negative pulse: 0-30% continuously adjustable

10. Voltage range: aluminum alloy: 700V, magnesium alloy: 550V, titanium alloy: 700V

11. Output waveform: DC waveform, single pulse waveform, DC superimposed pulse waveform, positive and negative double pulse waveform

12. Complete equipment protection function, with phase loss, short circuit, overcurrent, overvoltage, etc.

13. Supports local and remote control working modes. It has the timing and timing function of the oxidation process

14. Accurate constant current and constant voltage output characteristics, the control accuracy is within ±0.5V and ±0.5A respectively

How can customers choose high-frequency rectifiers correctly and reasonably?

Choosing electroplating rectifier power supply equipment also requires knowledge, and three requirements must be met:

1: To comply with the specifications required by the electroplating process, including the power size of the power supply, waveform indicators, and electrical performance Adjustable range of current voltage value, etc;

2: It is the reliability performance of the power supply itself, which mainly refers to the rationality, safety, and circuit characteristics of the structurePoint, cooling method, etc;

3: Consider the cost-effectiveness of its price.

Note: If the customer is not familiar or unsure, they can contact customer service for consultation

Multi-function controller

Intelligent control is convenient and customized to meet your needs

Gaohui intelligent control system supports customization

System program customization: Because the standards required by various industries are inconsistent, especially experimental power supplies, our company can customize system functions according to customer requirements, such as general timing, minutes, seconds, multi-segment timing, storage of multi-segment timing and corresponding preset constant current and constant voltage data, convenient for next call. Automatic reversal, reversal timing, etc. The following programs are for reference. If you need actual or customized details, please consult customer service.

1. Positive pulse: Peak current/voltage and average current/voltage display

2. Negative pulse: Peak current/voltage and average current/voltage display

3. Ampere-minute timing function (with alarm/silent mode) has ampere-hour display, ampere-hour running time, actual ampere-hour, set ampere-hour

4. 1.Process: Display the current process segment number (range: 1-20 segments)

2.Set time: Set the time of the current process (unit "seconds"/minutes)

3.Current segment: Display the current running process segment number (range: 1-10 segments)

4.Running time: The running time of the current process segment number (unit "seconds/minutes")

5. Positive and negative pulses set peak current A/voltage V0-rated value adjustable

6. Pulse frequency: 100-3000Hz adjustable

Positive and negative opening time: 0.1-99.9ms adjustable

7. Duty cycle: 0-100% adjustable

Positive and negative turn-off time: 0.1-99.9ms adjustable

8. Number of pulses: 0-9999 adjustable

9. Single-stage or multi-stage (1-10 stages adjustable) operation can be set

10. Constant current/constant voltage switch

11. Start/stop switch

12. Run/pause switch

13. Function: can enter contact us, system settings, process programming, historical data, historical faults, home page

Detailed display of core components

What makes us different,focusing on professional quality is better

IGBT Module

Using German Infineon/SAN RAX ,efficient and stable

Rectifier bridge module

Adopting Japanese Sanshe/Fuji Products,the performance is stable and can be used continuously for a long time.

Cooling fan

Powerful function,fast heat dissipation,low noise,waterproof and moisture-proof,the machine can work at full load for long time.

High power heat sink

Working at full load for a long time,Gaohui intelligent control system,multiple protections,stable heat dissipation,enhanced design,thickened heat dissipation aluminum plate.

Quality control

Every machines before leaving the factory has been inspected at all levels.

Synchronous energy saving technology

Adopting synchronous energy-saving technology,it has high working efficiency and saves electricity.the overall efficiency of the machine can reach 92%.

Three anti-treatment

The whole machine adopts anti-corrosion design, the chassis hardware adopts three-proof treatment, the whole machine structure is divided into high-pressure and low-pressure areas, the cooling fan mainly blows the heat dissipating aluminum material, not the electronic components, it has a long service life and is suitable for use in environments with strong acid or salt corrosion.

Output copper busbar tinned

The tinned copper busbar has good conductivity, anti-oxidation, anti-corrosion, electrical and thermal conductivity, and high temperature resistance.